Product

Home>Product

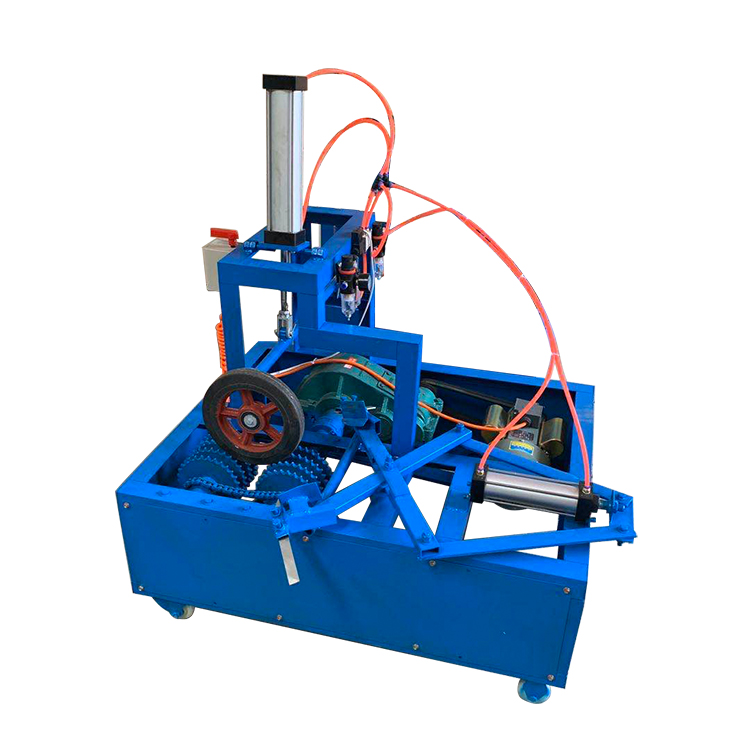

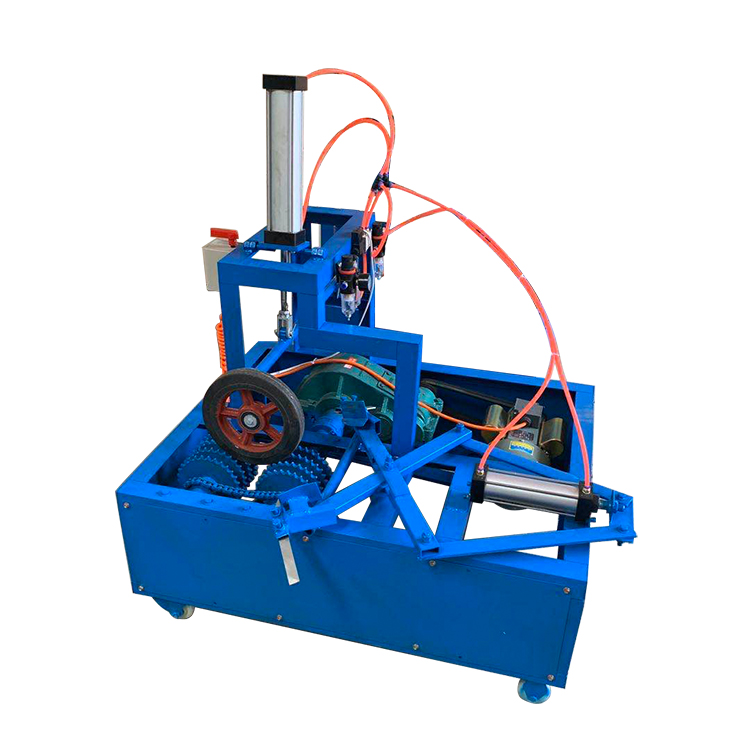

The tire cutting machine is used to cut and separate the sidewall and tire crown of waste tires for the next step of segmentation, and it is the first process of processing waste tires.

Equipment use

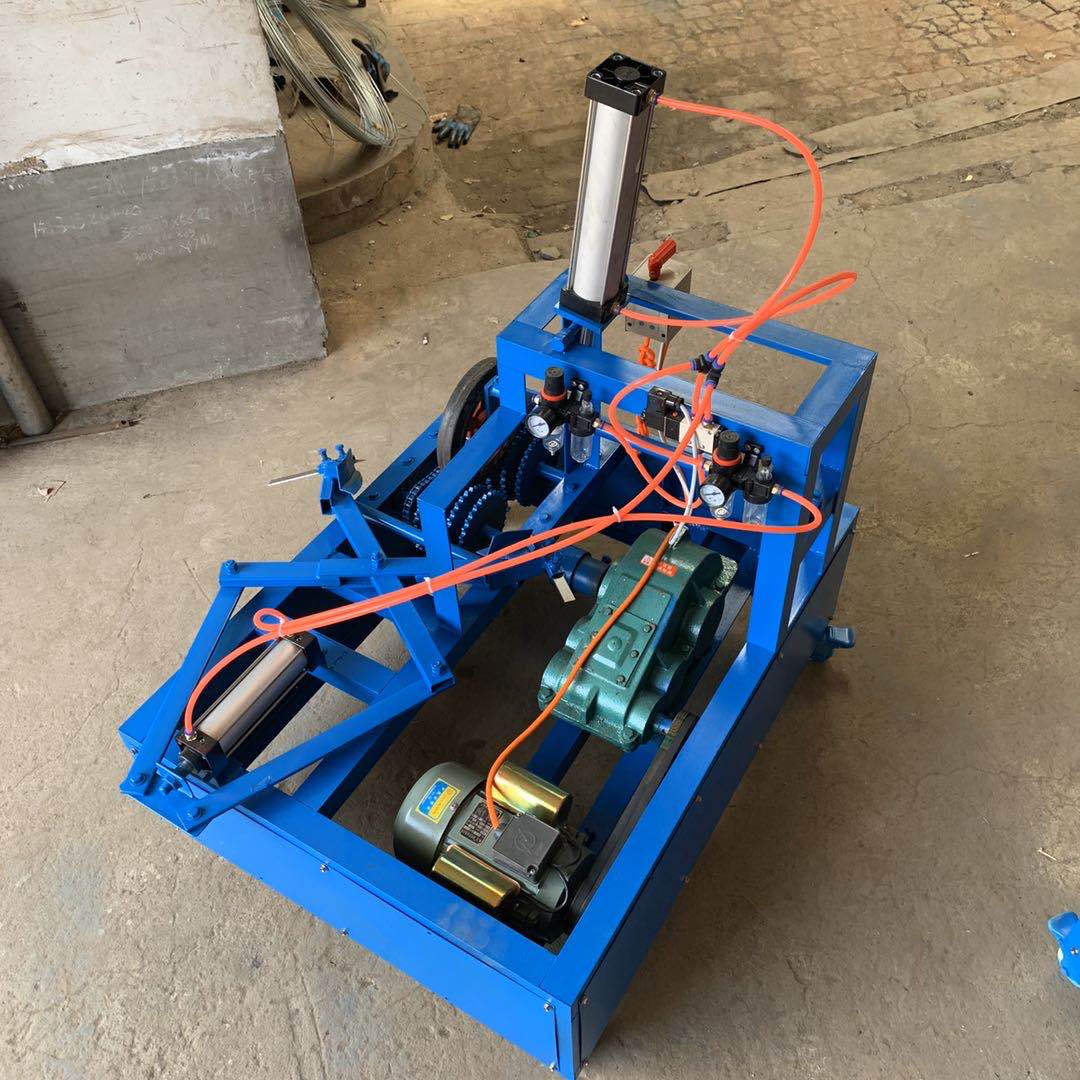

The motor drives the reducer to rotate the gear, and the tire is placed on the gear to rotate. The tire is controlled by the double cylinder of the pneumatic principle, and the tire bezel is cut on both sides at the same time. The cutting speed of each tire is 6-7 seconds.

Equipment operation

Put the waste tire on the disc platform, rotate the middle hand wheel, the four-claw clamp will firmly clamp the inner ring of the tire, turn on the power, the working platform will rotate, the cutting knife will enter the knife according to the need, and slowly cut into the tire, step by step , until the side of the tire is cut off. The tool is made of hard alloy, which is hard and durable, and can be re-grinded and used repeatedly.

Structural features of cutting machine:

1. The cutter body of the cutting machine is made of alloy steel blade, which is surfacing welded with highly wear-resistant alloy electrodes, and has a long service life.

2. The tire is easy to install, the reciprocating working stroke of the cutter is short, and the production output of the equipment is high

3. The operation is simple and convenient (manual or automatic).

4. The tool is made of hard alloy, which is hard and durable, and can be re-grinded many times.

Scope of application

Scrap tire cutting machine, with high degree of automation, is an innovative automatic cutting machine .Main cutting products: scrap small steel tyre, explosion-proof tyre.

Effect display

Product display

| Motor Power | 3 kW 4 grades, 380v or 220v can be customized according to customer needs. |

| Dimensions | 1.2 meters long, 1.1 meters wide and 1.3 meters high |

| Motor speed | 1440 |

| Voltage | 220V |

| Production efficiency | 1000 pieces/day |

| Weight | 160kg |