Steel Tube Shrinking Machine

Home>Steel Tube Shrinking Machine

1. This machine is used to process metal round tubes into tapered tubes and straight head tubes. 2. Manual and automatic models are available. 3. Low noise, easy operation, high output and stable performance. 4. The workpiece has very short forming time, high efficiency, smooth surface and no scratches. 5. Different molds can be selected to process metal pipes of different shapes, and the mold replacement is simple. 6. It is suitable for taper forming of pipe ends in automobiles, furniture, lighting and water pipes.

Product introduction

1. The tube shrinking machine is used to process metal round tubes into tapered tubes and straight tubes. There are manual and automatic options. It has the characteristics of low noise, easy operation, high output and stable performance.

2. The forming time of the workpiece is short, the efficiency is high, the processing surface is smooth, the workpiece has no scars, and the machine mold is easy to replace. With the cooperation of the corresponding mold, metal pipes of different shapes can be processed to meet different needs.

3. It is suitable for pipe end taper forming processing of pipe joints such as automobiles, furniture, lighting, water pipes, etc.

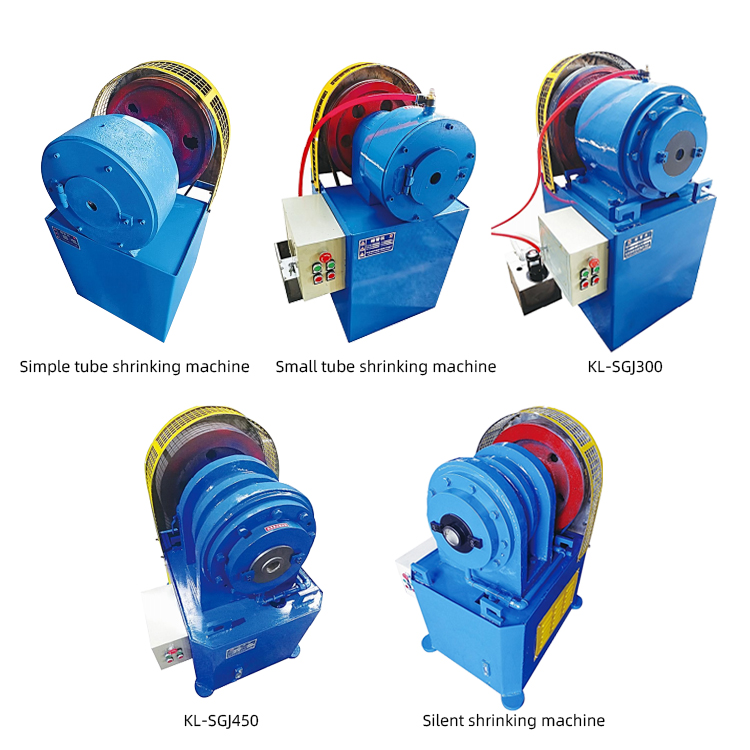

Tube shrinking machine display

For more models, please contact us.

| Model | KL-SGJ80 | KL-SGJ100 | KL-SGJ200 | KL-SGJ300 | KL-SGJ450 | KL-low noise300 |

| Maximum processing capacity | φ32×2.0 | φ48×2.5 | φ38×2.0 | φ40×2.0 | φ60×2.0 | φ42×3.0 |

| Maximum processing length | 80mm | 100mm | 195mm | 290mm | 450mm | 300mm |

| Molding time | 5-7 seconds/time | 5-7 seconds/time | 7-10 seconds/time | 7-15 seconds/time | 15-30 seconds/time | 7-15 seconds/time |

| Motor | 1.5kw | 3.0kw | 3.0kw | 4.0kw | 5.5kw | 4.0kw |

| Oil pump power | 40w | 40w | 40w | 40w | 90w | 90w |

| Spindle speed | 288 rpm | 288 rpm | 288 rpm | 288 rpm | 195 rpm | 195 rpm |

| Dimensions | 500×520×1000mm | 530×580×1150mm | 600×580×1150mm | 700×580×1200mm | 920×700×1300mm | 800×800×1300mm |

| Weight | 270kg | 400kg | 450kg | 694kg | 1278kg | 900kg |