Polishing machine series

Home>Polishing machine series

This machine is mainly used in: hardware, electroplating, steel wood furniture, standard parts, automobile and motorcycle parts and hydraulic transmission and other manufacturing industries. For a variety of axial, bar, pipe fittings cylindrical surface polishing, suitable for lathe processing after the work piece fine polishing.

Product description

This machine is mainly used in: hardware, electroplating, steel and wood furniture, standard parts, automobile and motorcycle accessories and hydraulic transmission and other manufacturing industries. It is suitable for polishing the outer surface of various shafts, bars, and pipe fittings, and it is suitable for lathe processing of workpieces after fine polishing.

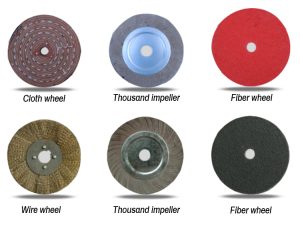

Polishing wheel display

We have different models suitable for different sizes of metal tubes, and the grinding wheels can be changed to achieve different polishing effects. We have thousands of impellers, nylon wheels, cloth wheels, wool wheels, etc. for you to choose from.

Product display

Small round tube polishing machine-KL-120

Large round tube polishing machine-KL-200

Double head round tube polishing machine-KL-250

Working Principle of Machine Tools

The grinding wheel (1000 impellers/polishing wheels) is used as the grinding tool, and the typical cylindrical grinding technology is adopted. The grinding wheel (1000 impellers/polishing wheels) can be roughly grinded, silently or polished by its material, granularity, hardness and contact mode. Multi-head linkage can double the processing efficiency.As long as the machine features: the speed of different wheels can be adjusted, it is suitable for polishing of workpieces of different sizes and diameters.

Transportation and lnstallation of Machine Tools

1. In transportation, it is necessary to tie firmly. When hoisting,it is necessary to use steel wire to pass through the bottom of the machine.The diameter of the steel wire is not less than 15 mm. It is necessary to keep balance and not to tilt.When loading and unloading forklift trucks, it is necessary to select the position of the center of gravity to prevent tilting.

2.When installing, the foundation should be balanced, the bottom should be all landed, and the machine should be kept level.When necessary, the ground silk should be struck.

3.When the machine is not in use for a long time, it should coat the swallow tail sliding surface with rust-proof oil, and pay attention to dust-proof and moisture-proof.

4.When equipped with an environmental protection cover, the equipment needs to be cleaned regularly, including lubricating oil: the dust in the motor is easy to enter and needs to be cleaned regularly, so that the life of the equipment will be greatly increased and unnecessary damage will be avoided.

| Small round tube polishing machine-KL-120 | |||||

| Model | Voltage | Power | Dimension | Weight | Working speed |

| KL-120 | 110/220/380V | 3KW | 900*700*1200mm | 160kg | 0-10m/min |

| Large round tube polishing machine-KL-200 | |||||

| Model | Voltage | Power | Dimension | Weight | Working speed |

| KL-200 | 110/220/380V | 4KW | 1200*800*1000mm | 250kg | 0-10m/min |

| Double head round tube polishing machine-KL-250 | |||||

| Model | Voltage | Power | Dimension | Weight | |

| KL-250 | 380V-Three-phase | 4KW | 1100*1200*1300mm | 400kg | |