Product

Home>Product

This machine is mainly for fruit and vegetable juice dehydration, using 304 stainless steel carefully build, reach the food level health and safety standards, widely used in fruit and vegetable beverage processing plants, fruit wine processing plants, wine processing plants and other industries need juice, dehydration.

Application and scope:

★Used for squeezing pineapple, apple, pear and other fruits.

★Used for pressing mulberry, grape, orange, orange and other berries.

★ Used for pressing tomatoes, ginger, garlic, celery and other vegetables.

★Screw advance extrusion.

★This machine can automatically finish the process of milling, extract juice and deslagging.

★ Contact with the material part of national standard 304 stainless steel manufacturing.

★ Frame material can choose 304 stainless steel, depending on customer requirements.

Features

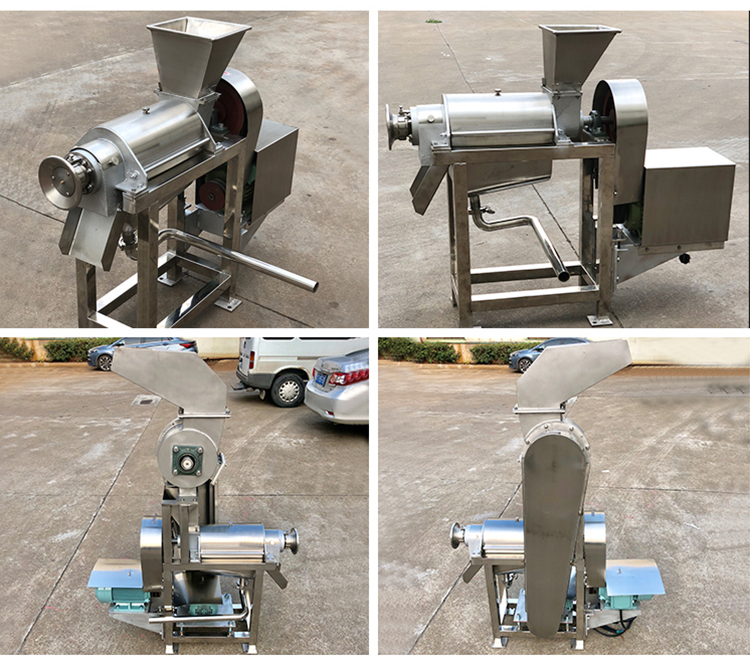

1. Advanced design, compact structure, elegant appearance.

2. The machine is composed of a crusher and a screw juice extractor, and completes the crushing, juicing, and slag discharge processes automatically.

3. It adopts conical screw, which has large production capacity and high juice yield.

4. High efficiency and energy saving, low noise and no pollution.

5. All the parts in contact with the material are made of stainless steel;

Product details

Working principle

The crushed pulp, juice and skin enter the screw juice extractor through the hopper. Since the bottom diameter of the screw gradually increases along the direction of the slag outlet, the screw pitch gradually decreases. When the material is pushed by the screw, the volume of the screw cavity shrinks, forming a Pressing of materials. The rotation direction of the screw spindle is clockwise when viewed from the feed hopper to the slag tank. Raw materials are put into the hopper and pressed under the propulsion of the screw, the squeezed juice flows into the juice container at the bottom through the filter screen, and the waste material is discharged through the ring-shaped gap formed between the screw and the pressure-regulating conical part. The axial movement of the pressure regulating head can adjust the size of the gap. Used clockwise (when looking from the slag discharge chute of the equipment to the end of the hopper and turning the handwheel bearing seat, the pressure regulating head is turned to the left, and the gap will shrink, otherwise the gap will become larger.) Change the size of the gap, that is, adjust the slag discharge However, if the gap is too small, part of the slag particles will be squeezed out through the filter together with the juice under strong extrusion. Although the juice output increases, the quality of the juice is relatively reduced, and the gap The size should be determined according to the user's specific process requirements. So as to achieve the purpose of automatic separation of juice and slag.

Product display

Packaging display

| Model | KLLX-0.5 | KLLX-1.5 |

| Capacity | 0.5t/h | 1.5t/h |

| Screw diameter | 87mm | 125mm |

| Screen hole size | 0.6mm | 0.6mm |

| Spindle speed | 400rpm | 400rpm |

| Power | 2.2kw | 5.5kw |

| Voltage | 220v/380v | 220v/380v |

| Dimension | 780*320*860mm | 1560*450*1340mm |

| Weight | 100kg | 240kg |