Construction machine

Home>Construction machine

The sand screen machine is to install the sand screen on the steel frame, and it is powered by the electric motor and the power transmission device. When materials (sand, grain, coal, etc.) are added to the screen, the rolling screen makes the materials roll and rotate. The material will then be screened on the conveyor belt, which will send the selected material out. In order to improve the quality of equipment and services; we support the customization of conveyor belts and rotary screens. In addition, the feeding hopper is enlarged and the frame of the sand screening machine is strengthened. Our sand sifter motors are high quality copper wire motors. The sand screening machine is suitable for sand mining, construction plants, coal mines, and grain screening.

Application range

The sand screening machine is suitable for sand mining, construction plants, coal mines, and grain screening.

← No Information

| Sand Screening Machine - Vibration Type | |||

| Model | KL-20X | KL-30X | KL-50X |

| Mesh size | 1.5cm | 1cm | 1.5cm |

| Main motor | 4kw | 7.5kw | 11kw |

| Mesh motor | 2.2kw | 4kw | 4kw |

| Size | 4.2*1.1*2.2m | 8.5*1.6*3.2m | 9.5*1.95*3.5m |

| Weight | 800kg | 1700kg | 1950kg |

| Capacity | 30-35 cubic meters/hour | 60-80cubic meters/hour | 100-120cubic meters/hour |

| Hopper | 1.1*2m | 1.5*3.2m | 1.6*3.4m |

| Conveyor | 0.5*8m | 0.8*3m | 1*18m |

| Vibration motor | 0.5kw | 0.5kw | 0.5kw |

| Annular | 4m | 8m | 9m |

| Sand Screening Machine - Drum Type | |||

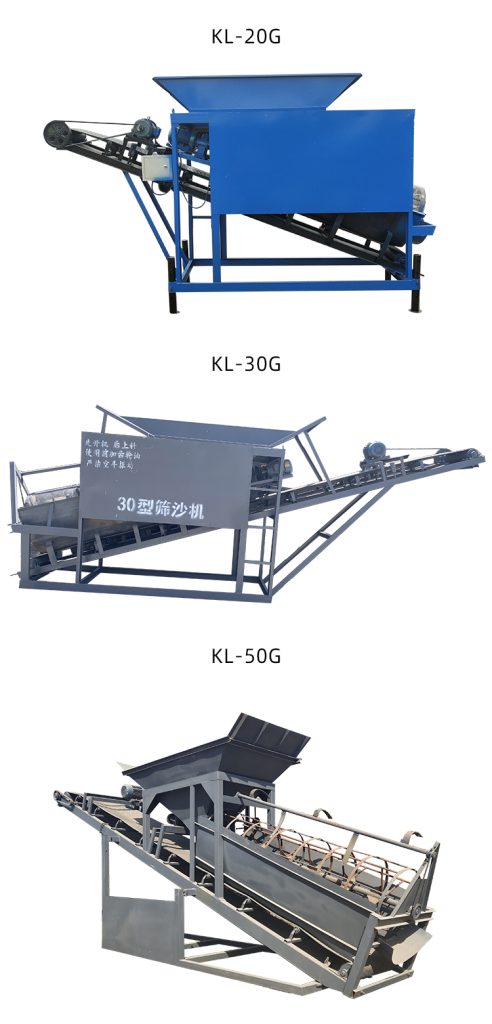

| Model | KL-20G | KL-30G | KL-50G |

| Dimensions | 4.3*1.1*2.3m | 8.2*1.6*3m | 9.2*1.9*3.5m |

| Hopper | 2m*1.1m | 3.5*1.5m | 3.6*1.6m |

| Motor Power | 7kw | 12kw | 15.5kw |

| Conveyor | 8.4m-0.5m | 16*0.8m | 18*1m |

| Diesel engine | 18hp | 22hp | 22hp |

| Conveying height | 2.2m | 3.2m | 3.3m |

| Screen size | 1.5m-0.6m | 3m-0.8m | 1*3.5m |

| Mesh size | Can be replaced | Can be replaced | Can be replaced |

| Capacity | 20-40 cubic meters/hour | 80-120 cubic meters/hour | 100-160 cubic meters/hour |

| Weight | 800kg | 1700kg | 1950kg |