Farm Machine

Home>Farm Machine

The process flow of the feed pellet production line is roughly the steps of raw material receiving, primary cleaning, crushing, mixing, granulation, cooling and screening, and packaging.

Tip:

Customize a scheme that suits you. What we need to know is:

1. What's your raw material?

2. What kind of animal are you feed? And how many animals are there?

3. Any speical demand?Please tell us.

Particle effect display

Product application

It is mainly suitable for medium and small-scale breeding professional households to process and produce various livestock and poultry and aquatic pellet feeds, which can reduce breeding costs. It can be used to raise rabbits, chickens, ducks, geese, fish, pigs, aquatic products, etc.

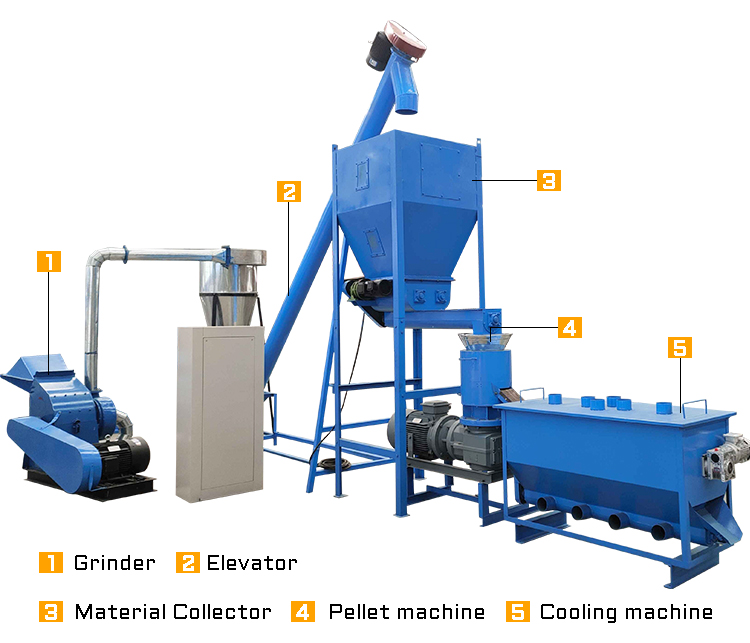

Type 1

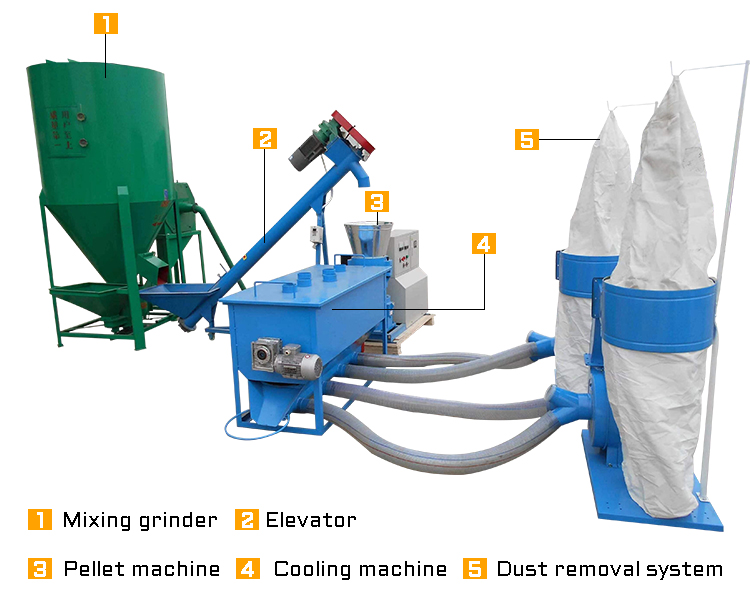

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

The process flow of the feed pellet production line is roughly the steps of raw material receiving, primary cleaning, crushing, mixing, granulation, cooling and screening, and packaging.

1. Primary cleaning of raw materials: The initial cleaning of raw materials is the first process of the production process. The function of this process is to ensure the timely supply of raw materials suitable for the next process by removing impurities. the

2. Raw material crushing: After the raw material meets the requirements for making granules, the raw material needs to be crushed until it meets certain requirements, because the crushing quality directly affects the quality of compound feed products and the quality of subsequent processes.

3. Feed mixing: The next thing to do is to mix various raw materials. Only after the raw materials are fully stirred evenly can the next step of granulation be carried out.

4. Feed granulation: Feed granulation is the core of the whole production line. After the raw material enters the granulation chamber, the high friction between the pressure wheel and the grinding plate produces high-strength pressure. The stirred raw material can be formed at one time, and after high temperature Gelatinization, granular material ripening degree is better. The pressed pellets can be fed directly. the

5. Feed cooling: Because the temperature of the pellets just produced by the pellet machine is relatively high, in order to ensure the quality of the feed, a cooling machine can be used to quickly cool and dry it, so that the feed is not fragile and easy to store.

6. Feed packaging: The processed finished feed needs to be packaged, which can ensure the quality and safety of the feed, and can also highlight the feed brand and increase the economic value of the feed pellets.