Product

Home>Product

The function of the frozen meat grinder is to finely chop the chunky raw meat according to the process requirements, and finely chop the meat, minced meat, fat and other raw meat, and at the same time, it can also chop and stir the seasonings, fillers and meat as required. Various granular meat pieces of different sizes are made and cooled for use in the next process. The frozen meat grinder can grind raw meat including pork, beef, boneless chicken, fish and other meats, which can meet the production needs of users for different meat products.

Introduction

1.High-quality stainless steel manufacturing, non-polluting materials, in line with food hygiene standards.

2.Time-saving, labor-saving, and can retain freshness and quality.

3.Short grinding time, low temperature, good for keeping fresh, extend the shelf life

4.The meat grinding machine can cut unfrozen meat or fresh meat directly into different size.

Commercial meat grinding machine has high universality and can be used universally in meat processing industry, also it has a big capacity.

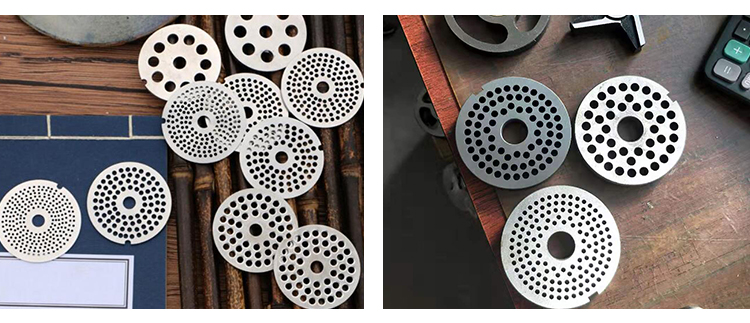

6.Meat grinding machine can produce different fineness of meat through by changing various of hole plate.

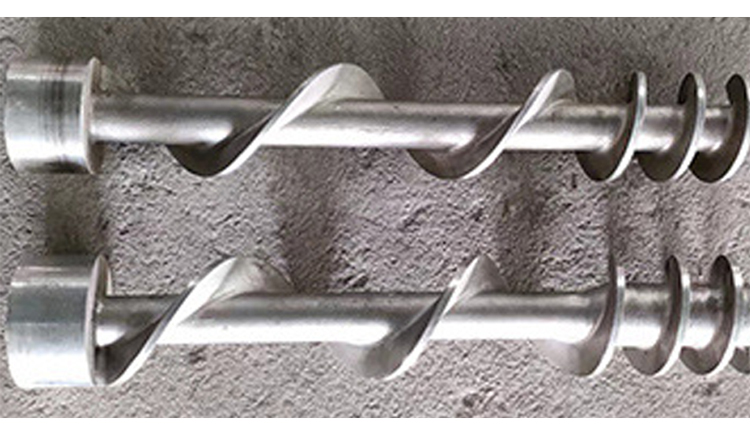

7.Safety meat chopper machine has simple structure but high performance,meanwhile it has unique screw, mesh and blade to keep the meat particle at low rising temperature during processing, preserve the good taste and nutrition of meat.

Meat mincing effect display

Working principle

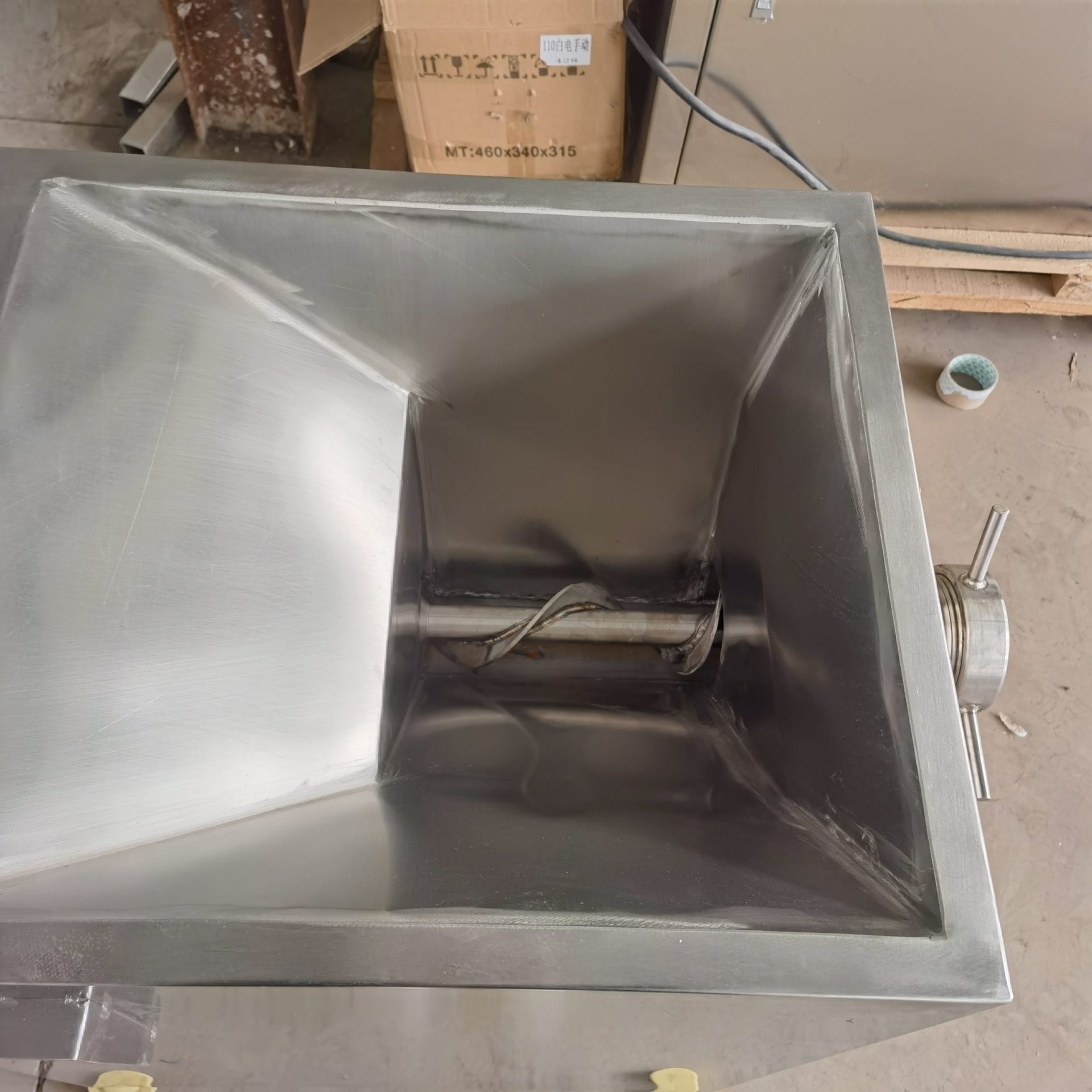

The meat grinder machine work mainly by rotating the screw raw material from the hopper tank push to the pre-cut hole plate,using rotating cutting blade and orifice hole edge on the formation of the shearing action will be chopped raw materials, and under the action of screw extrusion, continuous discharge materials will be closed.

Features

1.High-quality stainless steel manufacturing, non-polluting materials, in line with food hygiene standards.

2.Time-saving, labor-saving, and can retain freshness and quality.

3.Short grinding time, low temperature, good for keeping fresh, extend the shelf life

4.The meat grinding machine can cut unfrozen meat or fresh meat directly into different size.

5.Commercial meat grinding machine has high universality and can be used universally in meat processing industry, also it has a big capacity.

6.Meat grinding machine can produce different fineness of meat through by changing various of hole plate.

7.Safety meat chopper machine has simple structure but high performance,meanwhile it has unique screw, mesh and blade to keep the meat particle at low rising temperature during processing, preserve the good taste and nutrition of meat.

Replacing the auger and orifice

Display of various orifice plates

Reamer

Spiral chopping axis

Real shot show

| Model | KL-100 | KL-120 | KL-130 | KL-160 | KL-250 | KL-300 |

| Material | Outsourcing 201 stainless steel, inner frame carbon steel | Stainless steel | Outsourcing 201 stainless steel, inner frame carbon steel | Stainless steel | Stainless steel | Stainless steel |

| Motor power | 5.5kw | 7.5kw | 11kw | 15kw | 37kw | 55kw |

| Voltage | 380v | 380v | 380v | 380v | 380v | 380v |

| Rotating speed | 240r/min | 240r/min | 240r/min | 240r/min | 240r/min | 240r/min |

| Stranding range | φ4-φ20mm | φ4-φ20mm | φ4-φ20mm | φ4-φ20mm | φ4-φ20mm | φ4-φ20mm |

| Total weight | 230kg | 300kg | 300kg | 360kg | 1200kg | 1800kg |

| Production capacity | 300-500kg/h | 500-1000kg/h | 800-1500kg/h | 2000-3000kg/h | 2000-5000kg/h | 6000-8000kg/h |

| Dimensions | 940*600*940mm | 1100*1000*1310mm | 1130*720*1220mm | 1160*890*1270mm | 1800*1520*1600mm | 1900*1520*1800mm |