Farm Machine

Home>Farm Machine

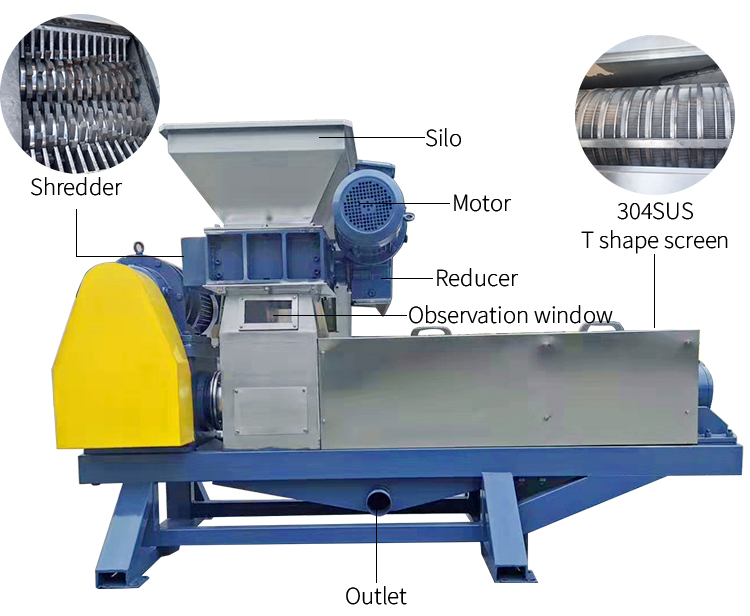

Kitchen waste shredder and dewatering machine is consist of food waste shredders and dewatering screw press. The two-in-one machine design save space and save process for convey crushed waste material to screw press,which is more efficiency. The food waste recycling machine can be used in the waste-to-energy application such as the application of commercial liquid food waste processed into bio-diesel, the waste-to-green application such as biodegradable organic waste composting, etc. We provide various capacity for your demand.

Product applicable

This machine is used for the solid-liquid separation operation of other macrocosmic materials containing certain fiber or viscous. Such as fermented grape pomace, ginger, spinach, rubber, Chinese herbal medicine, winter jujube and other fruits and vegetables containing certain fiber juice, It is also used for continuous juicing of seabuckthorn fruits that have been removed or contain a small amount of branchlets. The sieve holes are specially made according to the size of seabuckthorn seeds.

Product description

As for the large capacity shredding and screw press, we use do shredder and screw press seperate,On shredder can match several screw press machine by resonable designed feeding system.

Features

1. Low-speed double shaft shredding, material with fiber or without fiber can be crushed easily, high efficiency, strong processing capability.

2. Shredding and dewatering integration design, saves space and operation process.

3.Shredder and dewatering screw press can be independently disassembled, easily maintenance.

4 The blades uses high quality alloy steel, high hardness and toughness, blades material can be customed.

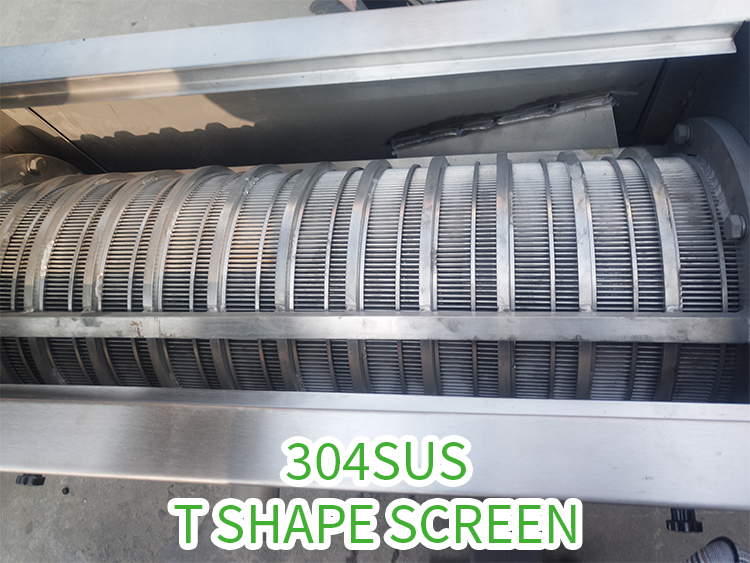

5. Material touched adopt 304stainless steel,shelf can be customed as 304stainless steel.

6. Pressure can be adjusted by change the space cone,when the space is smaller ,pressure will bigger.

Product display

| model | TZ180 | TZ260 | TZ350 | TZ420 | TZ500 | TZ600 |

| capacity | 0.2-0.5T/H | 1-1.5T/H | 2-3T/H | 3-5T/H | 8-10T/H | 10-15T/H |

| power | 3KW | 5.5KW | 7.5KW | 11KW | 18.5KW | 22KW |

| feed screw dia | 180MM | 260MM | 350MM | 420MM | 500MM | 600MM |

| feed screw pitch | 100MM | 150MM | 200MM | 210MM | 280MM | 280MM |

| feed screw rotation speed | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min |

| press screw dia. | 180MM | 260MM | 350MM | 420MM | 500MM | 600MM |

| press screw rotation speed | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min |

| Hy draulic cylinder diameter | Spring adjusted | ≤6Mpa | ≤6Mpa | ≤6Mpa | ||

| Hy draulic cylinder stroke | 0.55kw | 1.1kw | 1.5kw | |||

| oil pressure | ---------- | ---------- | ---------- | ≤6Mpa | ≤6Mpa | ≤6Mpa |

| Pressure needed | ---------- | ---------- | ---------- | 1-3Mpa | 1-3Mpa | 1-3Mpa |

| screen size | 0.2-1.5mm | 0.2-1.5mm | 0.2-1.5mm | 2.0*40mm | 2.0*40mm | 2.0*40mm |

| screen dia | 190mm | 270mm | 360mm | 430mm | 510mm | 610mm |

| dimension(mm) | 1700*500*800 | 2200*600*900 | 3500*700*1000 | 3580*1000*1470 | 3740*1200*1650 | 4500*1400*1650 |