Farm Machine

Home>Farm Machine

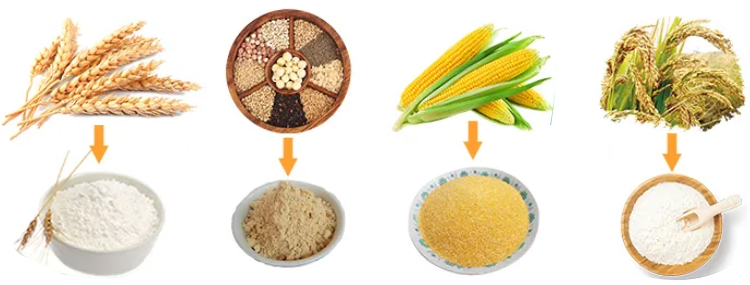

The grain powder grinder is suitable for the grinding of corn, beans, miscellaneous grains and wheat and other grain materials, and can also be used for dicing. Shredders are available in various specifications.

Working principle

Crush by impact. When the material enters the crushing chamber, it is impacted by the high-strength and high-frequency crushing tooth disc, and the collision and friction between the materials are quickly broken into powder or slurry, and are discharged through the discharge port under the action of centrifugal force and airflow.

Apply to

Suitable for crushing corn, rice, soybean, pepper, pepper and other grain materials.

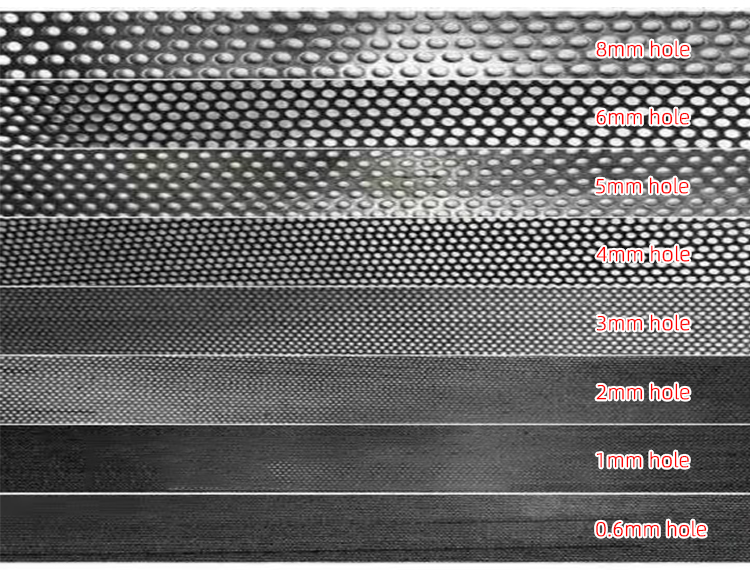

Screen display

The size of the output can be adjusted according to the size of the screen,Screen can be customized.

Detail

Specification

The vertical mill is equipped with a fully automatic self-suction grain tube, which makes feeding faster and more convenient.

Horizontal Grinding Mill

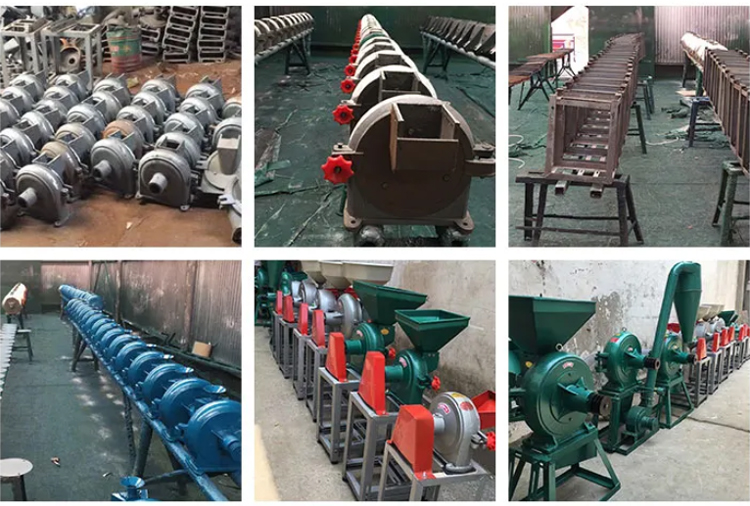

Factory Show

Safe operation and maintenance

1. Before starting the machine, you must read the instruction manual carefully, and make adjustments and normal maintenance. 2. The supporting power must meet the requirements, and it is not allowed to increase the spindle speed without permission.3. Check whether the running direction is the same as the cutting direction before starting the machine, otherwise it is strictly forbidden to start the machine.

4. Hard objects such as metals and stones must not be mixed in the materials that need to be cut sideways, otherwise it will cause damage to the machine.

damage.

5. After running the machine for a few hours, it is necessary to observe whether the parts are loose, and the bearings must be replaced regularly.

Fill with butter.

| Model | Sieve Diameter (mm) | Sieve Width & Length (mm) | Electric Motor Power (kw) | Spindle Speed (r/min) | Capacity (kg/h) | Overall Dimension (mm) |

| M-150 | 188 | 45-585 | 1.5 | 4000 | 30 | 330*690*500 |

| M-160 | 188 | 50-585 | 2.2 | 4000 | 50 | 360*710*520 |

| M-200 | 215 | 55-720 | 2.2 | 4000 | 60 | 410*560*570 |

| M-280 | 275 | 80-850 | 3.0 | 4000 | 100 | 560*570*580 |

| M-300 | 285 | 95-900 | 3.0 | 4000 | 150 | 570*580*590 |

| M-320 | 370 | 100-1150 | 7.5 | 4500 | 700 | 585*590*620 |

| M-360 | 400 | 100-1250 | 7.5 | 4500 | 1000 | 650*600*1200 |