Product

Home>Product

1.Put the raw materials into the pulper and add an appropriate amount of water to stir the waste paper into pulp. 2.The forming system is the process to produce the wet egg tray by forming machine. When the above forming moulds sink into the pulp tank, the negative-pressure vacuum pump will work on the the back of the forming mould, the pulp will be sucked and gathered on the mould surface to form the wet egg tray. 3.Then the wet trays are ready for sending to the metal dryer for drying.The metal dryer is six-layer.It occupies a small area; It saves about 30% energy than brick dryer.It can be designed to multi layer according to your requirements.

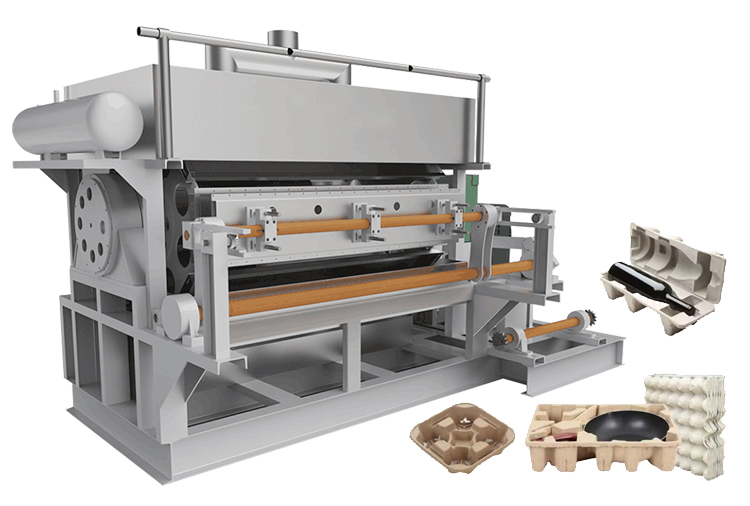

Egg Tray Making machine

1.Put the raw materials into the pulper and add an appropriate amount of water to stir the waste paper into pulp.

2.The forming system is the process to produce the wet egg tray by forming machine. When the above forming moulds sink into the pulp tank, the negative-pressure vacuum pump will work on the the back of the forming mould, the pulp will be sucked and gathered on the mould surface to form the wet egg tray.

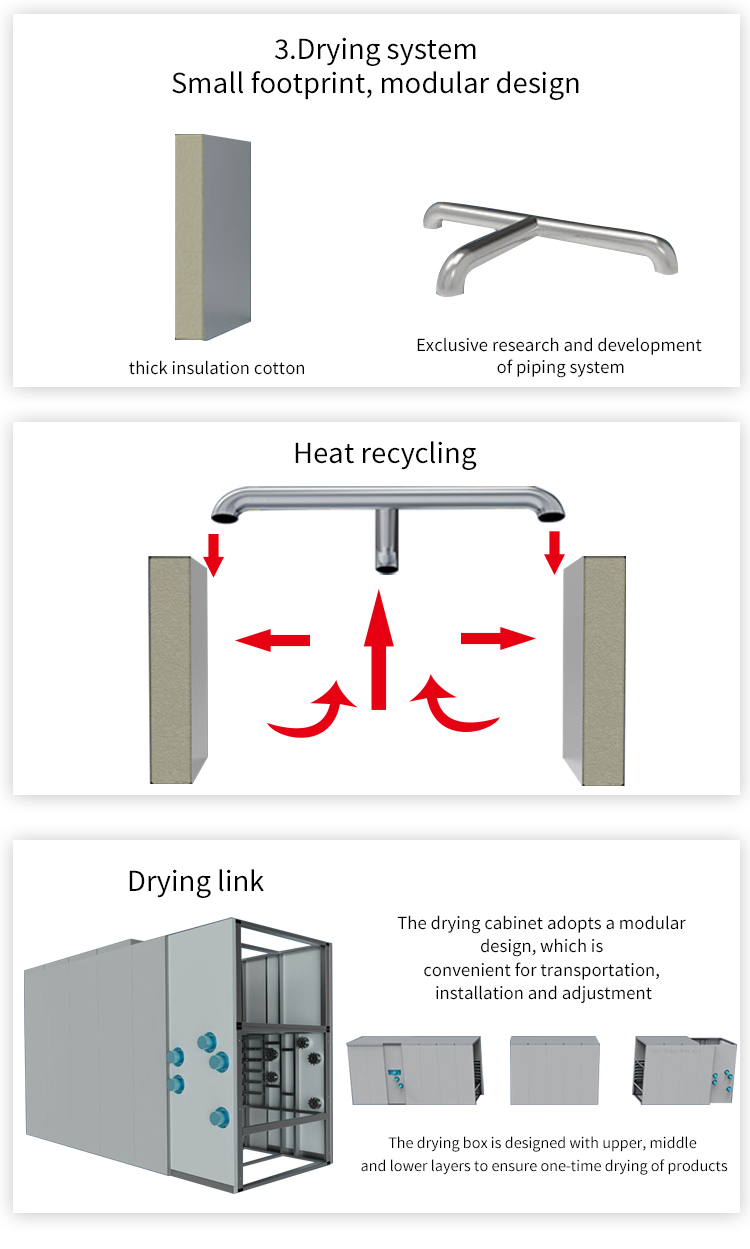

3.Then the wet trays are ready for sending to the metal dryer for drying.The metal dryer is six-layer.It occupies a small area; It

saves about 30% energy than brick dryer.It can be designed to multi layer according to your requirements.

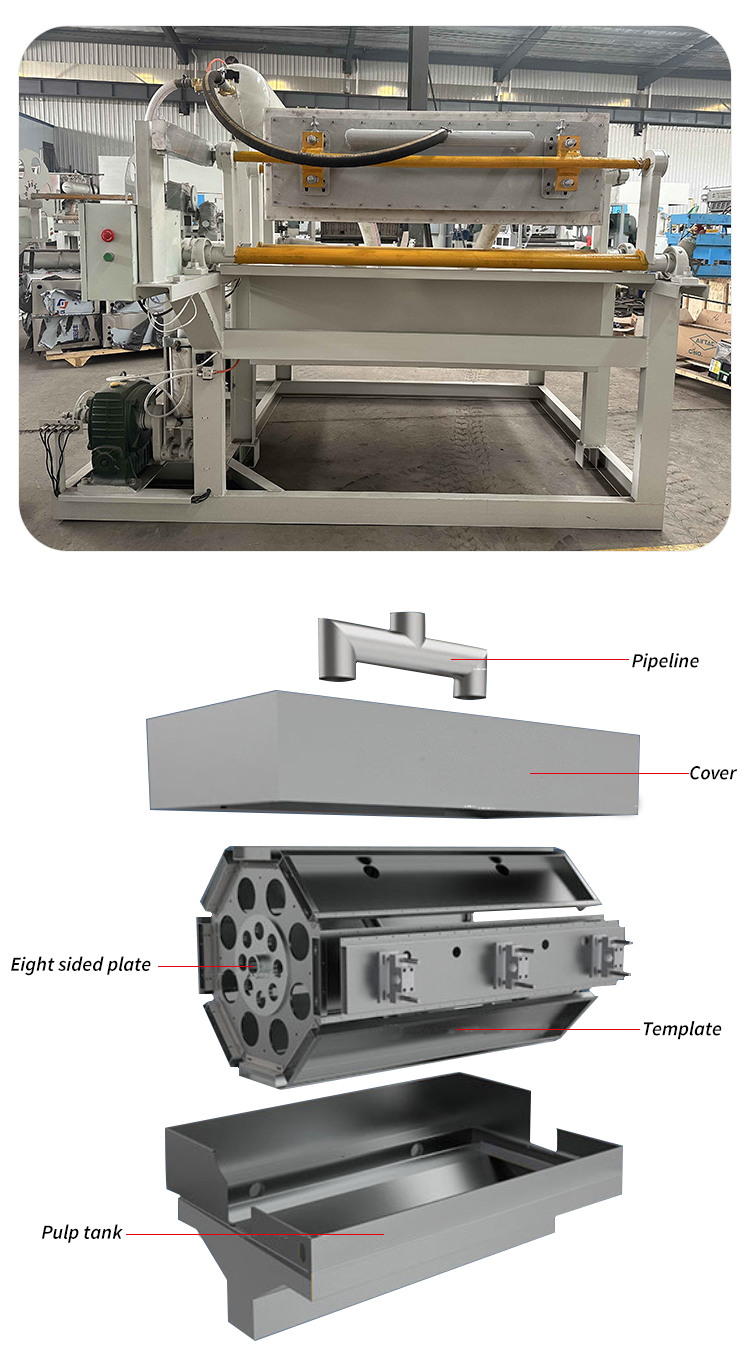

Forming machine real shot

Egg tray production line

Production flow chart

Four systems quality assurance

Thick stainless steel material strong and sturdy

1. Pulping system

Vertical high-consistency hydraulic pulper: mixing cage, dumpling knife, sieve plate, inclined plate are all made of stainless steel

Vertical high consistency hydraulic pulper model: 1m2R, 2m3, 5m3, 6m3, 8m3, 10m, different configurations for different output.

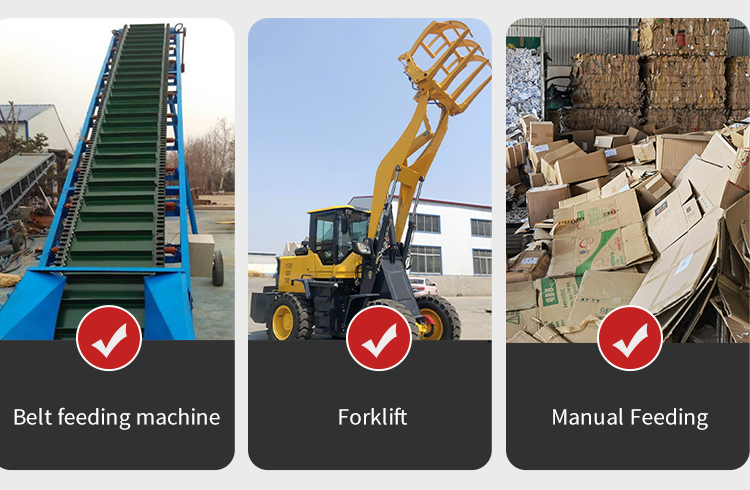

Fully automatic feeding link

Waste paper raw materials can be fed in three ways: belt conveyor, grab car, manual feeding, etc.

Whole body stainless steel material

2. Forming system

Fully automatic forming equipment, all materials except the fuselage frame are made of stainless steel.

Note: The slurry tank, formwork, upper cover and pipes are all made of stainless steel The molding machine comes with a fully automatic flushing function, intelligent speed regulation 17-24 boards per minute.

3.Drying system

Fully automatic packing system

4. Packing system

Fully automatic packing system, energy-saving labor

Note: configuration can be selected according to requirements.

| model | KL-4*8 | KL-5*8 | KL-6*8 | KL-8*8 |

| capacity | 4000-5000PCS/hr | 5000-6000PCS/hr | 6500-7500PCS/hr | 9500-10500PCS/hr |

| paper consumption | 335-420kg/hr | 450-500kg/hr | 550-625kg/hr | 790-875kg/hr |

| water consumption | 700-875kg/hr | 875-1050kg/hr | 1140-1320kg/hr | 1660-1850kg/hr |

| power consumption | 150kw/hr | 180kw/hr | 230kw/hr | 290kw/hr |