Bamboo processing machine

Home>Bamboo processing machine

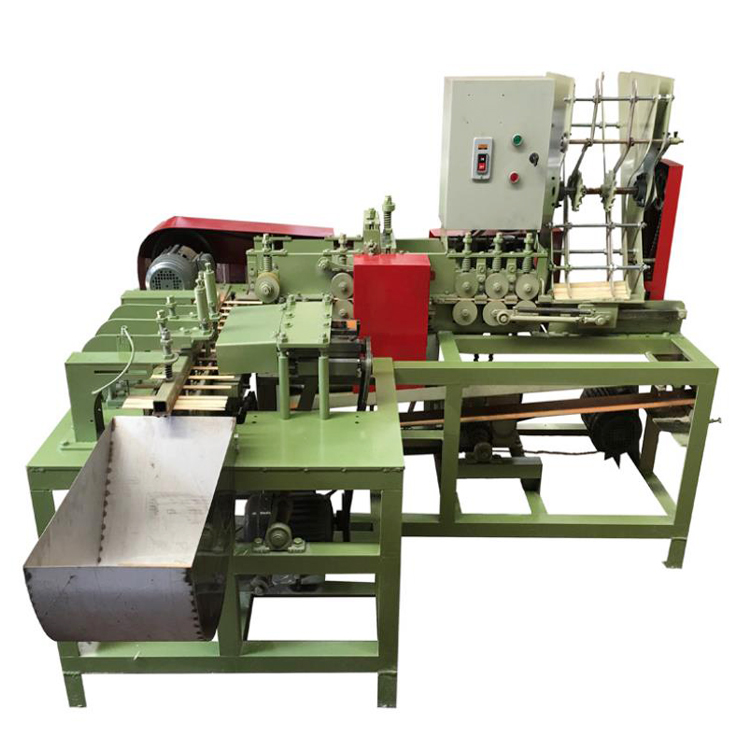

It is used to process thick bamboo strips into thin bamboo strips and sharpen them.

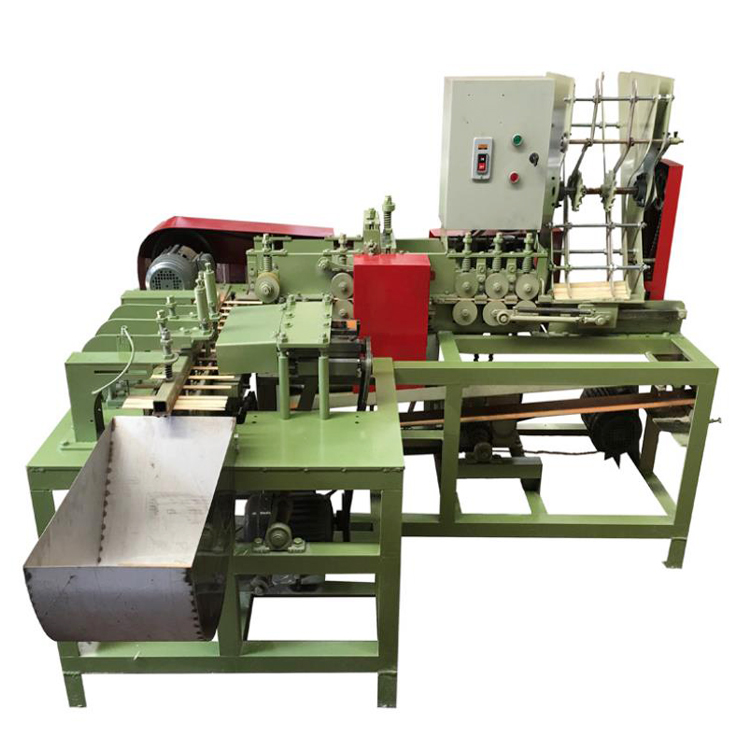

Effect display

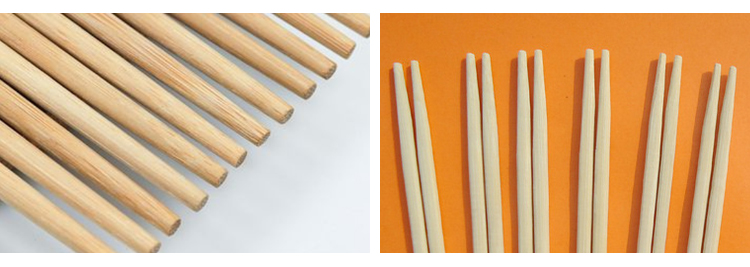

We also have disposable bamboo round chopsticks production line

Disposable bamboo round chopsticks production line

1. Technological process: Raw bamboo—feeding and sawing off—cutting bamboo strips—cutting knots at a fixed width—bamboo filament molding—bleaching—drying—sawing to length—polishing— Sharpening engraving - finishing packaging.

2. The above 9 machines are a production line. Except for the packaging machine, the output of the 8 machines is about 90,000-120,000 pairs in 8 hours, requiring 3-5 operators, male or female. The industrial electricity 380V is used, and the electricity consumption per hour of normal production is about 10-12 degrees. The plant area can be large or small, generally around 100 square meters.

3. Usually, about 3600-4300 pairs of round chopsticks with a diameter of 4.5-5.0 mm and a length of 190 mm can be produced per 100 kg of fresh moso bamboo. The general specifications of bamboo round chopsticks are: diameter 4.5-5.5mm, length 190-240mm.

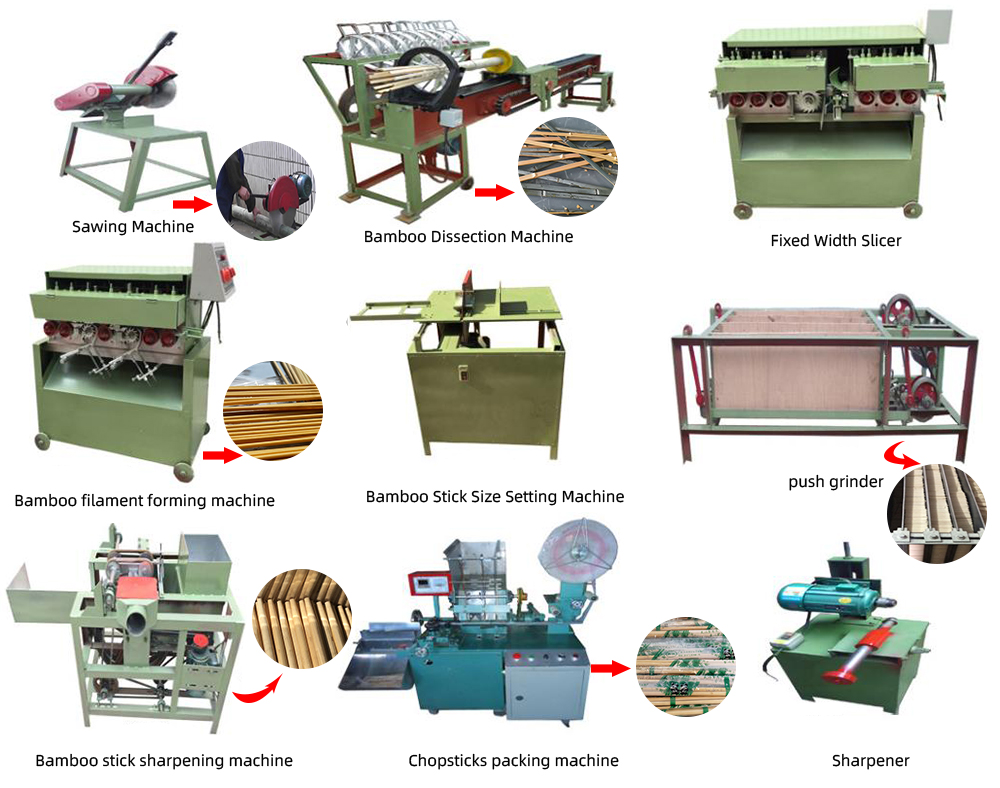

Parameters of Disposable Bamboo Round Chopsticks Production Line

| Name | Model | Mower(kw) | Weight(kg) | Dimensions (mm) |

| Sawing Machine | KL-DN-111 | 1.5 | 60 | 750*600*1300 |

| Bamboo Dissection Machine | KL-DN-102 | 3.0 | 530 | 3000*950*1200 |

| Fixed Width Slicer | KL-DN-103 | 3.0 | 260 | 1180*680*1100 |

| Bamboo filament forming machine | KL-DN-104 | 9.1 | 400 | 1020*690*1050 |

| Bamboo Stick Size Setting Machine | KL-DN-105 | 0.75 | 75 | 800*700*900 |

| Push grinder | KL-DN-106 | 2.20 | 240 | 2200*1050*850 |

| Bamboo stick sharpening machine | KL-DN-107X | 2.8 | 280 | 1400*850*1050 |

| Chopsticks packing machine | KL-DN-553 | 0.45 | 110 | 1300*600*1300 |

| Sharpener | KL-DN-108 | 0.37 | 50 | 450*400*870 |