Product

Home>Product

This machine is mainly used to crush waste foam products such as foam fast food boxes, cake boxes, foam packaging materials, thermal insulation materials and foam materials, omentum white pollution garbage into small pieces, and crush the crushed foam particles at the same time. The powder is blown into the foam granulator for re-granulation, so as to achieve automation, save manpower, and increase production. It is an ideal crushing equipment in the foam granulator production line. This machine has the characteristics of large output, high efficiency, low dust, low noise, low energy consumption, convenient operation and low maintenance cost.

Features

1. The fine crusher is divided into two stages to crush the cutter shaft structure to improve efficiency;

2. The upper knife group is double-axis, with automatic feeding function;

3. The discharge is pumped by fan to reduce dust;

4. The equipment is equipped with a shock absorber, and the running noise is small;

5. The knife set is specially treated to improve the service life;

6. Coarse crushing and fine crushing are carried out at the same time, and the output particles are small.

Applicable scope

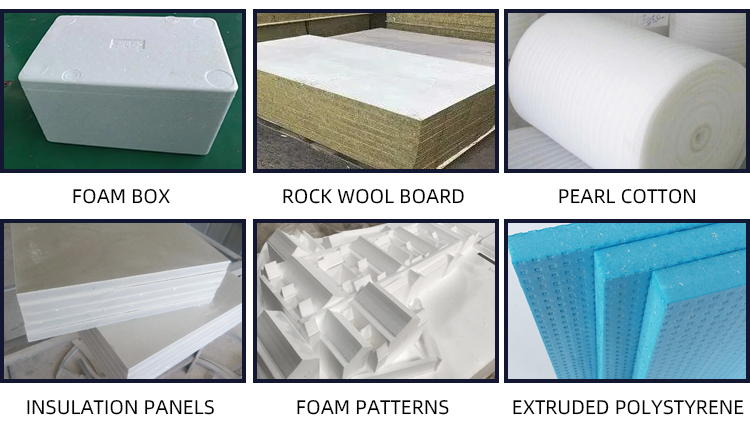

The scope of application includes the crushing of EPS, XPS, EPP, EPE, PU and other materials. It is widely used in waste foam scraps, packaging foam, disposable lunch boxes, polyurethane insulation boards, extruded boards, lost foam and rock wool boards, and foam boxes. , heat insulation board, KT board, heating material and other recycling industries adopt a simple and efficient structure, which can directly put the waste foam material into the feed port of the crusher.

Shattering Effect Display

Show more

| Model | Output | Power | Weigh | Inlet Diameter | Dimension |

| KL-1000 | 300-320kg/h | 5.5kw | 200kg | 1m | 1300*1100*650mm |

| KL-1200 | 450-500kg/h | 7.5kw | 260kg | 1.2m | 1500*1300*700mm |

| KL-1500 | 700-750kg/h | 11.0kw | 400kg | 1.5m | 1800*1600*800mm |