Farm Machine

Home>Farm Machine

Feed crushing and mixing machine is a complete set of feed processing equipment integrating crushing and mixing. It is suitable for small and medium-sized farms and feed processing plants.

Scope of application

It is suitable for family farmers, small farms and professional processing households.

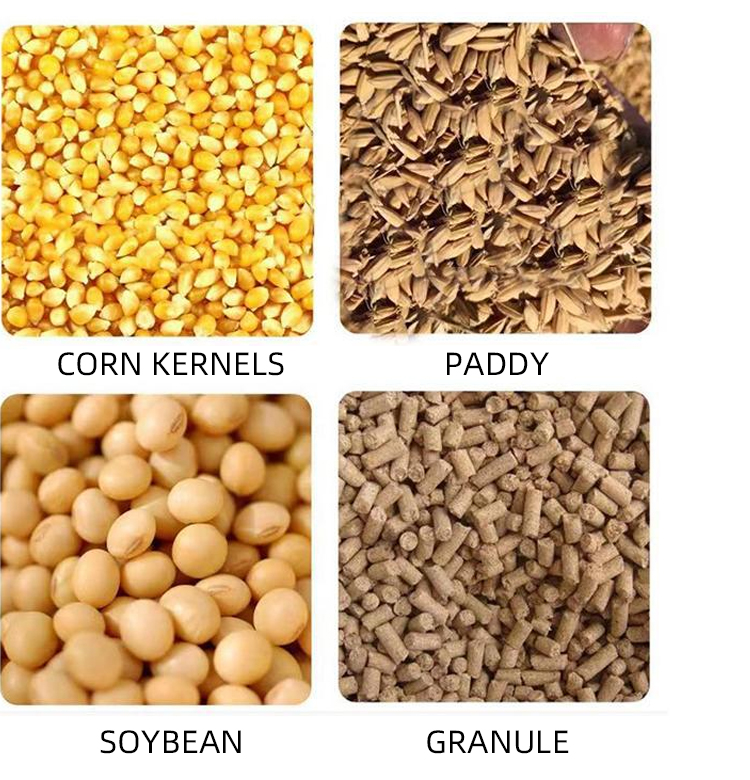

Mainly crush corn kernels, soybeans, rice and other granular crops.

Feature

1. The device adopts the structure of rotation, throwing and the like, so that the material is tumbling up and down.

2. The left and right are staggered to achieve the purpose of quickly and uniformly mixing the materials, and has the advantages of reasonable structure.

3. Convenient use, small occupied area, low noise, no dust, energy saving and environmental protection.

4. It is convenient to load and unload materials, durable, easy to clean residual materials, easy to maintain and maintain, and multi-purpose.

Working principle of feed mixer

1. Crushing mechanism: There are automatic feeding and manual feeding. When the material is sucked or sent into the crushing chamber, it is quickly crushed into powder or granular under the continuous blow of the rotary blade and the rubbing of the crushing chamber. Then, under the action of centrifugal force and airflow, it is discharged into the impeller box through the sieve hole and then enters the delivery pipe.

2. Mixing mechanism: When the material propeller rotates, the material is forcibly sent into the material delivery pipe by the impeller chamber, and when it is lifted to the top by the rotary conveyor, the material in the stirring atomization box is lifted up and down and rotated in a circular motion. Form a mixing process, the effect is very uniform, very ideal.

The shell of the feed machine is welded with high-quality materials. The feed port is on the top of the pulverizer, which can be matched with various feeding structures. The hammers are symmetrically arranged; Under the impact of the powerful hammer and the friction of the sieve plate, the material is gradually crushed, and under the action of centrifugal force and air flow, it is discharged through the bottom outlet

Feed mixer use safety precautions

1. In order to avoid accidents during the transportation, loading and unloading of the machine, it is necessary to check whether the bolts and nuts of each part are loose, whether the flat teeth, round teeth, and spindle nuts are loose before use. Turn the pulley by hand to check whether the machine has any collisions.

2. Whether the rotation of the machine is flexible, whether there is any debris in the machine, start the machine and idle for 3 minutes, and then start the operation if there is no abnormal phenomenon. 3. When working, you must pay attention to clearing the sundries in the materials. It is strictly forbidden to enter the machine with iron and stones to avoid damage to the machine and people.

4. The fabric bag should have a length of more than 4 meters and a diameter of 0.6 meters. The fabric should not be too dense, and the material should be discharged in time during use to ensure that the bag has sufficient air permeability. 5. Feeding should be uniform, pay attention to the power load, so as not to choke. When crushing particles, the pumping plate regulator can be used to adjust the feeding amount.

6. Hammer type: When one corner wears and affects the working efficiency, the opposite side of the hammer can be turned around (4 groups are adjusted together at one time when turning, so as not to cause rotor imbalance). Replace the hammers and replace them all.

7. Grease should be added before starting the machine every day, and the condition of the shaft should be checked after 500 hours of use. When installing the sieve, the side with burrs should be installed on the side with burrs. According to the fineness of crushed materials, choose different screens.

| Model |

KL-500F |

KL-750F |

KL-1500F |

|

Grinder Power |

3kw |

7.5kw |

11kw |

|

Mixer Power |

3kw | 3kw | 3kw |

| Capacity |

300-400kg/h |

500-750kg/h |

1000-1500kg/h |

|

Volume(Cubic meters) |

1 | 1 | 2 |

|

Mixing time(min/batch) |

30-40 | 30-40 | 30-40 |

| CV | ≤13% | ≤13% | ≤13% |

|

Drivemode |

Belt | Belt | Belt |

| Size | ¢1000*2300 | ¢1000*2300 | ¢1260*2800 |

| Weight |

350kg |

450kg |

600kg |

| Available in a variety of colors.

|

|||