Product

Home>Product

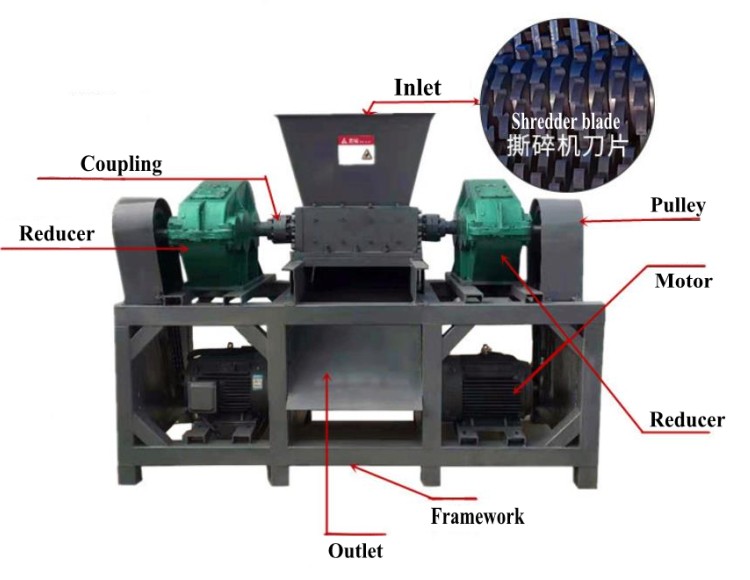

The twin-shaft shredder shreds various soft and hard materials by using two sets of cutter discs composed of high-grade alloy steel. Mainly shreds plastic packaging drums, rubber tires, basket materials, large rolls of films, and large bundles of agricultural films. Plastic mulch film, large bale of plastic film, large bale of woven bag, roll film, paper, fiber, wood, etc. This machine has the characteristics of large output, low energy consumption, low noise, low dust, etc., so it is widely used in coarse and medium crushing operations such as solid waste, plastics, waste household appliances, paper, leather, wood, rubber and so on.

Features

1. The double-shaft shredder uses thick and heavy moving knives, which has high crushing efficiency, and its knives are cast with alloy steel, which is strong and has a long service life.

2. The frame plate is thick, can resist high torque, and is strong and durable.

3. It adopts microcomputer (PLC) automatic control, and has various functions of start, stop, reverse and overload automatic reverse control.

4. It has the characteristics of low speed, high torque, low noise and less dust.

5. Easy to adjust, low maintenance cost, economical and durable.

6. The thickness of the tool and the number of claws can be changed according to different materials.

Product analysis

Application of Shredder

1 · Wood: wood scraps, wooden pallets, solid wood, branches

2 · Barrel products: plastic bucket, metal bucket, paint bucket, IBC bucket, trash can

3. Garbage: domestic waste, medical waste, kitchen waste, industrial waste, garden waste

4. Plastic products: various plastic films, plastic bags, woven bags, plastic bottles, plastic frames, plastic blocks, plastic cans,

5 · Metal products: aluminum profiles, oil filters, car shells, cans, metal cans

6 · Paper: Newspaper, cardboard, corrugated paper, copy paper

7 · Electronic appliances: refrigerator, circuit board, laptop computer case, TV case, CD disc

8 · Glass products: glass wool, glass cup, glass bottle

9 · Rubber: tires, various rubber products

The twin-shaft shredder drives the cutter head to rotate at a high speed through the motor. During the high-speed rotation of the movable knife, the relative motion with the fixed knife is formed. The gap formed between the movable knife and the fixed knife causes the material to shred and cut. In this way, large pieces of material are crushed, and the crushed material is filtered and output through the screen.

Tool cutting structure:

1. Fixed knife: prevent the material from winding around the knife shaft

2. Moving knife: cutting material at high speed

3.Spacer: Control the clearance of moving knife

Influence of tool shape on output size

1. The thickness of the moving knife determines the discharge width. The thinner the thickness of the moving knife, the narrower the width of the material.

2. The distance between the tip of the moving knife determines the length of the material. The smaller the distance between the point of the knife (the more the number of blades), the shorter the length of the material.

Product Image

Shredder use and maintenance instructions:

1. Before starting the test run, it is necessary to strictly check whether the installation of each part of the machine meets the requirements, whether the screws and bolts are loose, and the belt can be lightly pulled by hand to see if there is any phenomenon such as bumping the shell. At the same time, check the direction of rotation, and it is strictly forbidden to crush flammable and explosive materials to avoid accidents.

2. During the production, uniform feeding should be maintained to ensure the crushing quality and normal production. At the same time, it is strictly forbidden to overload the motor to ensure the normal operation of the machine.

3. In addition to frequently checking the fastening and looseness of various parts, you should also pay attention to checking the wear of the wearing parts. If the wear is serious, you should replace it in time to avoid damage to the main parts, and take necessary fire prevention measures.

4. Due to the high speed, in addition to the correct and firm installation, good lubrication should be maintained at the same time to maintain the normal operation of the machine. Under normal circumstances, it is normal for the bearing temperature not to exceed 70 degrees. Add butter and molybdenum disulfide to the main engine bearing once a week, and the effect of high-speed butter is better.

| Shredder Model | KLPS-600 | KLPS-800 | KLPS-1000 | KLPS-1200 | KLPS-1600 |

| Diameter Rotary | 255mm | 255mm | 300mm | 300mm | 300mm |

| Number Rotary | 60pcs | 78pcs | 96pcs | 114pcs | 150pcs |

|

Rotating Shaft Shredder |

90rpm |

90rpm | 90rpm | 90rpm | 90rpm |

|

Number of Fixed Knife |

4pcs |

4pcs | 4pcs | 8pcs | 8pcs |

| Maximum yield | 650kg/h | 900kg/h | 1000kg/h | 1200kg/h | 1500kg/h |

| Feeding caliber | 700×800mm |

880×1100mm |

1070×1150mm |

1280×1300mm |

1650×2000mm |

| Power of main motor | 18.5KW×2 | 22KW×2 | 30KW×2 | 37KW×2 | 45KW×2 |

| Host weight | 4000kg | 5400kg | 6200kg | 8000kg | 9500kg |