Product

Home>Product

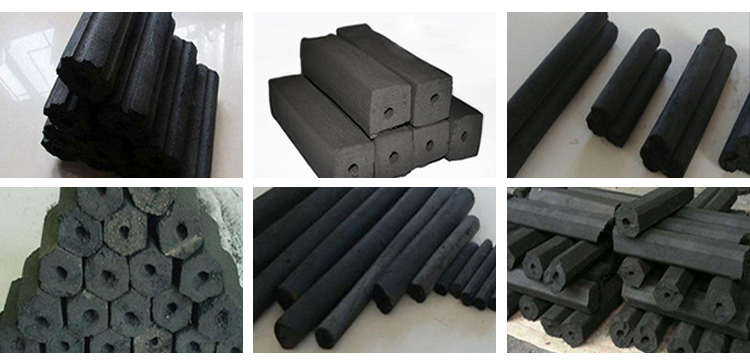

This machine is a kind of briquette machines which can press the powder of coal, charcoal, carbon blackand other materials into rods which has certain intensity, the shape of rods can be round, six prismatic,square and so on.

Applicable materials

The equipment is suitable for branches, straw, straw, peanut shells, tree trunks, cotton straw and tea seed shells, fruit shells, weeds, leaves and other raw materials containing biomass fibers that can produce charcoal.

Finished product display

Technical features of charcoal machine:

1. The lead of the feed screw is large, the feed is fast, and the lead of the propulsion screw is small, saving power.

2. The shaft seat and the cylinder body are rigidly connected, with high concentricity, anti-reverse thrust, and stable machine.

3. The part that needs to be sealed adopts a fault structure, and the dirt is leaked from the disconnected part.

4. Driven by a hydraulic coupling, the machine runs smoothly with low noise and also plays the role of overload protection.

5. The head and the cylinder body are connected with a snap ring structure and a bolt structure, which can be selected and ordered according to the user's needs.

Machine display

*Characteristics of charcoal machine:

1. This product has the characteristics of reasonable design, reliable manufacturing quality, simple structure, convenient operation, small volume, less land occupation, labor saving and power saving.

2. The designed automatic control electric heating device can randomly adjust the dry humidity of the material to ensure the stable forming of the material and improve the work efficiency.

3. The main parts of this product are made of wear-resistant materials and have been specially treated, so they can be produced by continuous pressing and are durable.

4. It is suitable for compression molding of various biomass raw materials, with low energy consumption and high production efficiency.

5. Change the three bearings of the old-fashioned movement to four, which increases the stability and durability of the machine. 6. Change the old-fashioned oil-coated lubrication to oil-immersed lubrication. As long as there is no shortage of oil, it can be used for many years. 7. Increase the screw pitch to increase the feeding amount, thereby greatly increasing the output.

8. The structure of the forming cylinder is improved, the friction between the machine and the raw material is reduced, and the density of the mandrel is increased.

| Model | MBJ-140 |

| Power | 11kw |

| Capacity | 1-2 t/h |

| Briquette Diameter | 20-80mm |

| Weight | 620kg |