Farm Machine

Home>Farm Machine

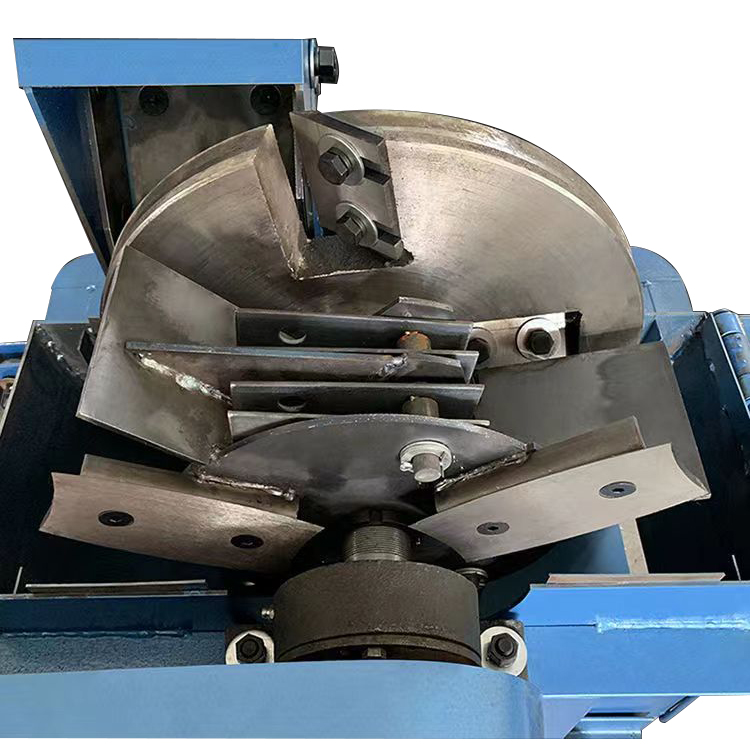

The wood shredder adopts blade cutting, high-speed airflow impact and collision double crushing functions in one, and can complete the sorting process of trace materials at the same time. During the cutting and crushing process of the blade, the rotor generates high-speed airflow, which rotates with the cutting direction of the blade, and the material is accelerated in the airflow, and at the same time repeatedly impacts the crushed material to accelerate the crushing rate of the material.

Scope of application

Wood grinder are widely used in mechanism charcoal plants, Buddha incense plants, wood-based panel plants, biological power plants, paper mills, sawmills, feed plants, farms, mushroom edible fungi bases, landscaping projects, processing of wood in the lower corner of the furniture factory.

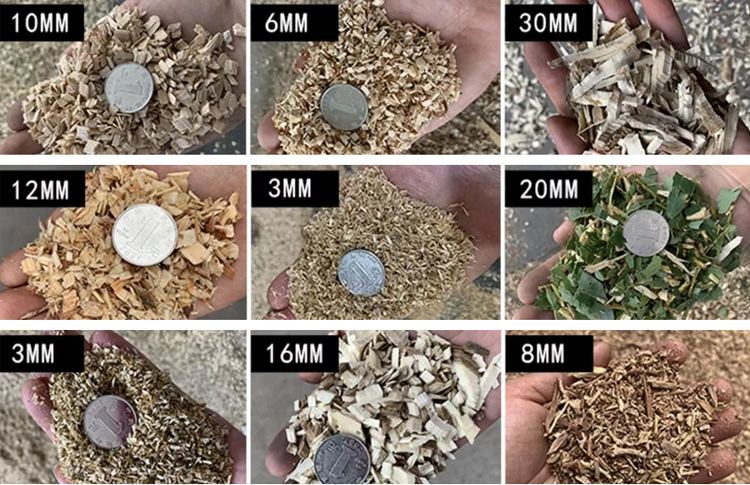

Wood crusher crushing effect

Main structure

Cutter display inside the machine cavity

Different models of product display

| Model | KL-420 | KL-500 | KL-600 | KL-700 | KL-1000 | KL-1200 |

| Cutter diameter (mm) | 425 | 500 | 600 | 600 | 800 | 100 |

| Number of blades (pieces) | 4 | 4 | 4 | 6 | 8 | 8 |

| Material port size (mm) | 160*155 | 205*185 | 230*195 | 230*195 | 280*290 | 385*385 |

| Spindle speed/min | 2600 | 2500 | 2500 | 2100 | 1800 | 1800 |

| Motor power (kw) | 7.5-15 | 18.5-22 | 22-30 | 37 | 75-6 | 90-6 |

| Output per hour (T) | 0.6-0.9 | 1-1.5 | 1.5-2 | 2.5-3 | 5-6 | 7-8 |

| Dimensions (cm) | 120*125*92 | 160*88*100 | 165*105*100 | 185*115*105 | 118*110*95 (without bottom shelf) | 142*150*122 (without bottom shelf) |

| Fineness after crushing (mm) | The fineness after crushing depends on the size of the sieve hole. The machine is equipped with a 16mm sieve by default. The size of the sieve can be selected according to requirements, each with 3, 6, 8, 10, 12, 16, 20, 30mm sieve holes Available sizes. | |||||