Product

Home>Product

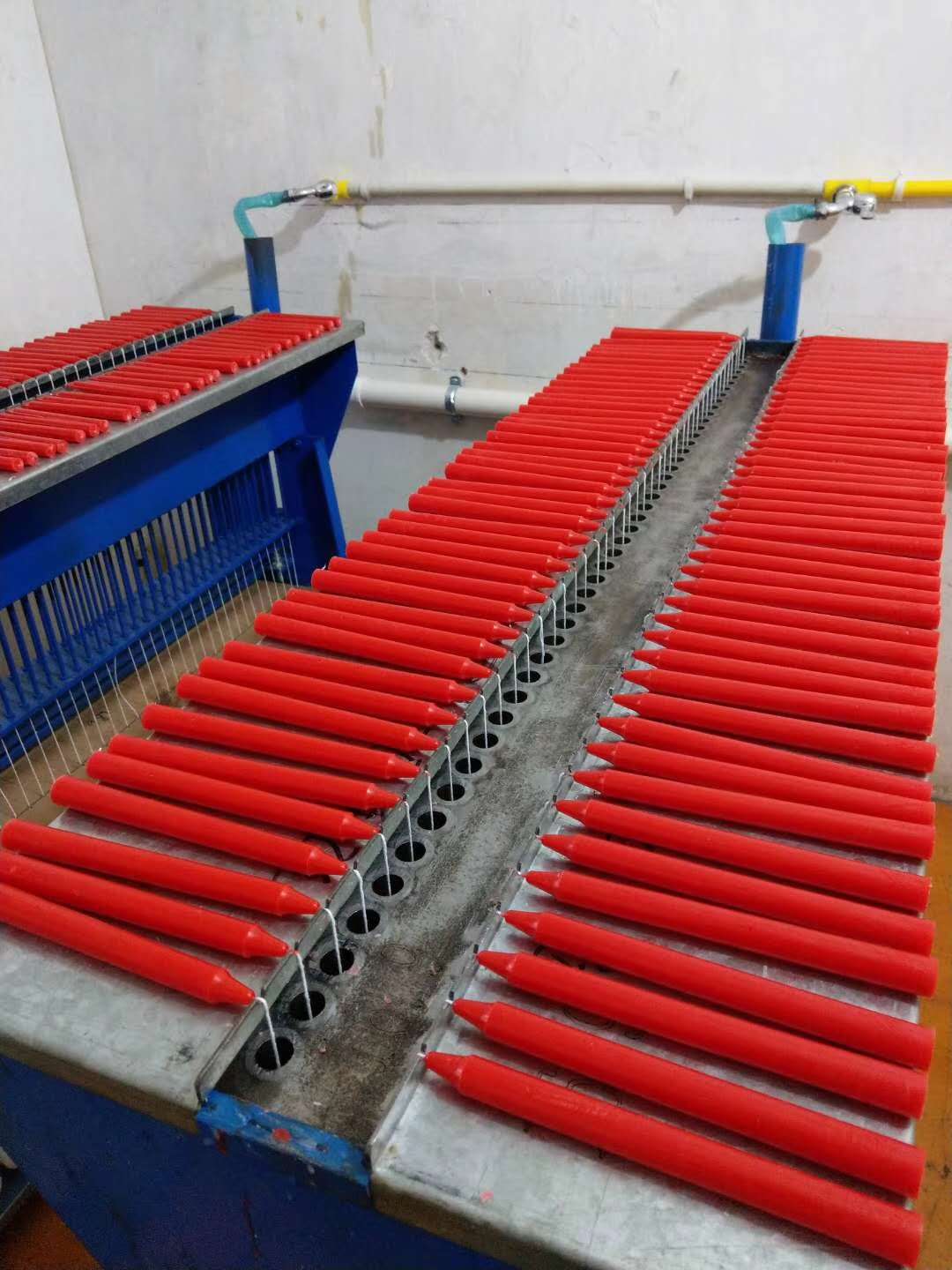

Candle machine at a time out of the number of candles, out of the model candles are placed on the tray, high efficiency, skilled workers can operate at the same time 8 candle machine. The candle machine is made from fine stretching seamless copper tube and lead alloy, etc, through finishing machining, the machine crown bar adopts seamless steel pipeline, which can be adjusted up and down to change candle length.

Candle manufacturing process

1.Melt the paraffin wax in a wax pot.

2.Insert the wick into the mold of the candle machine.

3.Pour the melted paraffin oil into the wax machine mold.

4.After cooling, take out the candles from the mold of the candle machine.

5.Carry out exterior decoration, arrange and package the finished products.

The advantage that does candle factory: investment saves, suit family to make, raw material can reuse, do not need special technology, profit cycle is short.

Product display

♦Application:

Main products : lighting candle machine, birthday candle machine, cup candle machine, cylindrical candle machine, cone candle machine, tea wax machine, Buddhist candle machine, craft candle machine, craft candle mold, spiral candle machine. the moulds customized .we can manufacture machines according to customers provided candle samples and drawings.

|

Type |

Tube mould number |

Size |

Mould material & production structure |

|

200 |

1400*430*900mm |

|

|

120 |

||

|

120 |